Bar ø Across Ribs Nominal Cross Section Area As Yield Load Py fyAs Ultimate Load Pu fuAs Nominal Weight Mill Length Direction of Thread mm mm mm2 kN kN kgm m L R 1100 MPa fu Hot-Rolled Threadbar. Grade 75 80 and 100 conform to the.

DYWIDAG-Systems International has developed the GEWI Plus systems to meet the challenges set by restrictions in construction space and higher demands on load capacities of steel elements.

Dywidag bar capacity. DYWIDAG THREADBAR Reinforcing Steel Hardware Dimensions THREADBAR. Bars are made of prestressing steel Y 1050 H according to prEN 10138-4. A total of 878 Type 32 WS Y 1050 H DYWIDAG Bar Tendons were used.

Coupler with Locknuts Locknuts can also be used each side end of the coupler similar to hex nuts. The splice will develop the full load ultimate load of the bar in tension and about half the ultimate load in compression. High capacity DYWIDAG Bar Anchors.

Using two washers in a set. THREADBAR Reinforcing System. Prestressing bars are hot-rolled tempered from the rolling heat stretched and annealed with a circular cross section.

A total of 878 Type 32 WS Y 1050 H DYWIDAG Bar Tendons were used. The thread is identical to DYWIDAG Thread in terms of dimensions and tolerances and can be combined with all accessories. A GEWIPile is a drilled and grouted micropile less than 12 inches in diameter that is centrally reinforced with either one or a group of two or three high tensile strength DYWIDAG THREADBAR.

Together with matching accessories it is used by formwork manufacturers around the world and has proven itself countless times on jobsites. THREADBAR Reinforcing Steel is available in Grades 75 and 100 for sizes 6 through 11 Grade 80 and 100 for 14 through 20 and Grade 75 for 24 and 28 bar. The ground anchors consist of 75mm Ø DYWIDAG Prestressing Steel Threadbars that were pregrouted at the DSI factory in Southam to ensure compliance with BS80812015 for permanent anchors.

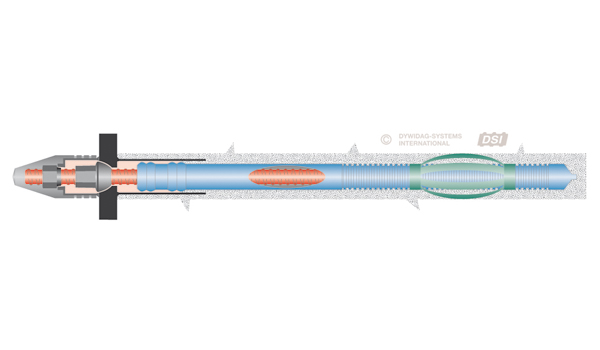

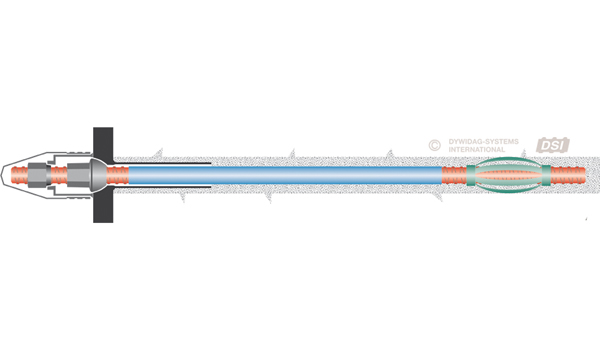

DYWIDAG Threadbar Anchors are an actively tensioned ground anchor system and correspond to DIN 4125 and EN 1537 regulations. DYWIDAG Threadbar Anchors are an actively tensioned ground anchor system and correspond to DIN 4125 and EN 1537 regulations. DYWIDAGs high load capacities allow greater spacing for fewer ties and lower labor costs.

Due to the active tensioning anticipated deformations of the system and deformations at the civil engineering measure are. Due to the active tensioning anticipated deformations of the system and deformations at the civil engineering measure are minimized or entirely eliminated. DYWIDAG ties are 50 lighter than conventional ties.

DYWIDAG Bar Tendons enhance Load-Bearing Capacity of the A44 Approach Bridges near Leiden. At the upper side of the girders a massive anchor plate with two welded couplers was used as a dead-end anchor. DYWIDAG THREADBARS may be stressed to the allowable limits of ACI 318.

Threadbars and plain bars are available in mill lengths up 18 m and may be cut to specified lengths before shipment to the jobsite. The bridge accommodating the A44 Motorway near the city of Leiden northeast of The Hague is. DYWIDAG THREADBARS - TECHNICAL DATA METRIC UNITS April 16th 2018 DSI Surrey BC STEEL GRADE Nominal Bar Diameter Max.

GEWI Plus offers an increase in strength compared to traditional GEWI Threadbars. The bars are available in mill lengths and can be cut to fit andor spliced at any point. A decisive advantage of the DYWIDAG Threadbar is its coarse thread that does not run around the complete circumference of the bar.

The MUKUSOL Threadbars continuous thread is cold-rolled onto the steel and not cut. This applies both to temporary structures. MUKUSOL Threadbars can be welded without any problems in common conditions.

DYWIDAG Threadbar with hot-rolled continuous thread on both sides. Consult with your local DSI Sales Engineer. Their lightweight and high strength features save on shipping and labor costs.

Consult DSI Sales Engineer for oversize hardware. Components of the THREADBAR Reinforcing System are manufactured in the United States and Canada exclusively by DYWIDAG-Systems International. Solutions for larger bars and angles are available.

The huge overhang of the roof is supported by backstays that had to be anchored down in the ground by 12 No. Each post-tensioning stirrup consisted of 2 vertical DYWIDAG Bar Tendons that were installed vertically along the girders. Each post-tensioning stirrup consisted of 2 vertical DYWIDAG Bar Tendons that were installed vertically along the girders.

Ultimate load of the bar in tension and compression. DYWIDAG THREADBAR Properties and Hardware Dimensions. GEWI Plus has a yield strength of 670Nmm 2 an increase of 34 and an ultimate strength of.

DYWIDAG THREADBAR Properties and Hardware Dimensions. Nuts and couplers lengths are for uncoated bars. The final working prestress level depends on the specific application installation procedure stressing sequence and the rigidity of the structural system.

The maximum jacking stress temporary may not exceed 080 f pu and the transfer stress lock off may not exceed 070 f pu. DYWIDAG THREADBAR and 1 ¾ and 45 ft for 2 ¼ 2 ½ and 3 bars. GEWIPile can carry loads up to 300 tons in compression or tension in relatively small boreholes.

At the upper side of the girders a massive anchor plate with two welded couplers was used as a dead-end anchor.

Dywidag Threadbar Technical Data Metric

Dywidag Threadbar Technical Data Metric

Dywidag Threadbar Anchors Dsi Emea

Dywidag Threadbar Anchors Dsi Emea

Dywidag Threadbar Anchors Dsi Emea

Dywidag Threadbar Anchors Dsi Emea

Dywidag Threadbar Anchors Dsi Emea

Dywidag Threadbar Anchors Dsi Emea

Metric Steel Properties Dsi Canada

Metric Steel Properties Dsi Canada

Dywidag Threadbar Anchors Structurae

Dywidag Threadbar Anchors Structurae

Dywidag Threadbar Anchors Structurae

Dywidag Threadbar Anchors Structurae

High Capacity Dywidag Bar Anchors For Liverpool Fc S New Main Stand Dsi Emea

High Capacity Dywidag Bar Anchors For Liverpool Fc S New Main Stand Dsi Emea

Dywidag Expansion Anchor Dsi Canada

Dywidag Expansion Anchor Dsi Canada

Dywidag Bar Tendons Enhance Load Bearing Capacity Of The A44 Approach Bridges Near Leiden Dywidag Systems International Group

Dywidag Bar Tendons Enhance Load Bearing Capacity Of The A44 Approach Bridges Near Leiden Dywidag Systems International Group

High Capacity Dywidag Bar Anchors For Liverpool Fc S New Main Stand Dsi Emea

High Capacity Dywidag Bar Anchors For Liverpool Fc S New Main Stand Dsi Emea

0 Response to "Dywidag Bar Capacity"

Posting Komentar